A Comprehensive Manual for Premium denim Selvedge Fabric

Ever questioned the reason certain trousers feel like they’re built for endurance a lifetime? Everything revolves around the materials and artistry. Take, for instance, the rising trend of superior selvedge. It’s not merely ordinary textile—it’s a testament to excellence and legacy.

Currently, a growing number of people are choosing these everlasting textiles for their durability and classic selvedge denim fabric appeal. Be it that you are a DIY sewist or a denim lover, there’s something special about using high-quality natural fiber and thread. It isn’t solely concerned with making jeans; it’s about crafting a legacy.

Here at Core Fabrics, we’ve assembled a selection of 14.25oz eco-friendly cotton and flexible options. These fabrics are ideal for everything from raw jeans to designer jacket blueprints. Eager to discover the world of exceptional fabrics? Let us delve in.

What Is Denim Selvedge Fabric?

Why do some trousers stand out with their unique, naturally edged edges? The secret resides in the selvedge denim, a superior material celebrated for its enduring strength and vintage appeal. In contrast to conventional textiles, such material is fashioned using traditional methods that have proven their worth.

What Selvedge Denim Means

Selvedge denim is created using old-style shuttle looms, which generate slender widths of about 30-35 inches. These looms weave the textile in a manner that ensures self-finished borders, often highlighted by a characteristic red line. This process ensures the material is tightly woven and extremely robust.

Modern looms, alternatively, yield expansive material but do not offer the same level of craftsmanship. Subtle irregularities in selvedge, like misaligned seams or irregular surfaces, are celebrated as elements of its beauty. This approach, termed “wabi-sabi”, celebrates the beauty of organic flaws.

Production of Selvedge Denim

The production of selvedge denim requires a detailed process. Traditional shuttle looms interlace the weft thread back and forth, resulting in a dense and sturdy fabric. This method contrasts with contemporary machines, which prioritize rapid output over durability.

Labels such as Karson Denim preserve vintage Japanese weaving techniques from the 90s. They deliberately incorporate flaws to maintain the authenticity of the fabric. Every item is graded on a four-point system, guaranteeing it fulfills the top criteria of superiority.

| Attribute | Selvedge Denim | Contemporary Denim |

|---|---|---|

| Width | 30-35 inches | 60+ inches |

| Construction Technique | Traditional Shuttle | Contemporary Loom |

| Finish | Irregular, Flawed | Even |

| Durability | Superior | Average |

“The allure of selvedge lies in its imperfections—each flaw tells a story skill and legacy.”

The Legacy of Selvedge Denim

From humble beginnings to global acclaim, the story of these fabrics is rich and inspiring. What started as rugged attire in 17th-century France evolved into a mark of classic elegance and artistry.

Beginnings in Craftsmanship

The foundation of this material trace back to Nîmes, France, where it was referred to as “serge de Nîmes.” First intended for laborers, it was crafted out of hardwearing cotton and stitching. Its strength made it a favorite among workers during the Gold Rush.

In the 20th century, it had become a staple for trousers. The closure of the Cone Mills White Oak factory became a pivotal moment. This transition enabled Japanese artisans to restore classic fabric-making practices.

Modern Developments in Denim

Post-WWII, Japan developed a deep appreciation for retro American culture. Skilled workers revitalized antique looms to create authentic reproductions. This commitment to craftsmanship secured the perseverance of selvedge as a unique product.

Currently, breakthroughs from Italy and Turkey have launched eco-friendly combinations and elastic options. These modernizations have enhanced the allure of this classic material. At Core Fabrics, we gather worldwide, from Montréal to Asia, to offer you the finest quality.

“Selvedge’s story is a celebration of the lasting worth of craftsmanship and legacy.”

The Benefits of Selvedge Denim?

Why does selvedge denim stand out in the universe of top-tier fabrics? Its unique qualities and unmatched durability make it a favorite among enthusiasts and designers alike. Be it that you are crafting jeans or a structured jacket, this material delivers a blend of tradition and contemporary charm.

Unique Qualities of Selvedge Fabric

Selvedge denim is celebrated for its tight weave, which boosts durability and wear patterns. In contrast to common fabrics, rainbow selvedge denim is produced using traditional shuttle looms, yielding a tightly packed and extra robust material. Such a process guarantees that all products boast a singular finish and character.

Here’s what makes it special:

- Coarse, stiff raw denim contrasts with laundered, relaxed stretch options.

- The sanforization process ensures predictable sizing, while untreated fabrics provide a shrink-to-fit adventure.

- Weight options range from 9.5oz Eco Finish to 14.25oz Organic, meeting varied requirements.

Durability and Longevity

One of the key attributes of selvedge denim is its long life. The tighter weave both reinforces strength and permits unique fading patterns over time. This renders it a wise purchase for those seeking classic garments.

Key points to consider:

- Mid-weight fabrics from 12oz to 14oz work well for tailored jackets and evolving jeans.

- For classic jean longevity, the 14.25oz True Indigo is a top recommendation.

- Eco-friendly options, like recycled cotton and indigo blends, add sustainability to your wardrobe.

Core Fabrics offers an assortment of products tailored for every requirement. From raw to sanforized, each piece is crafted to deliver exceptional quality and value.

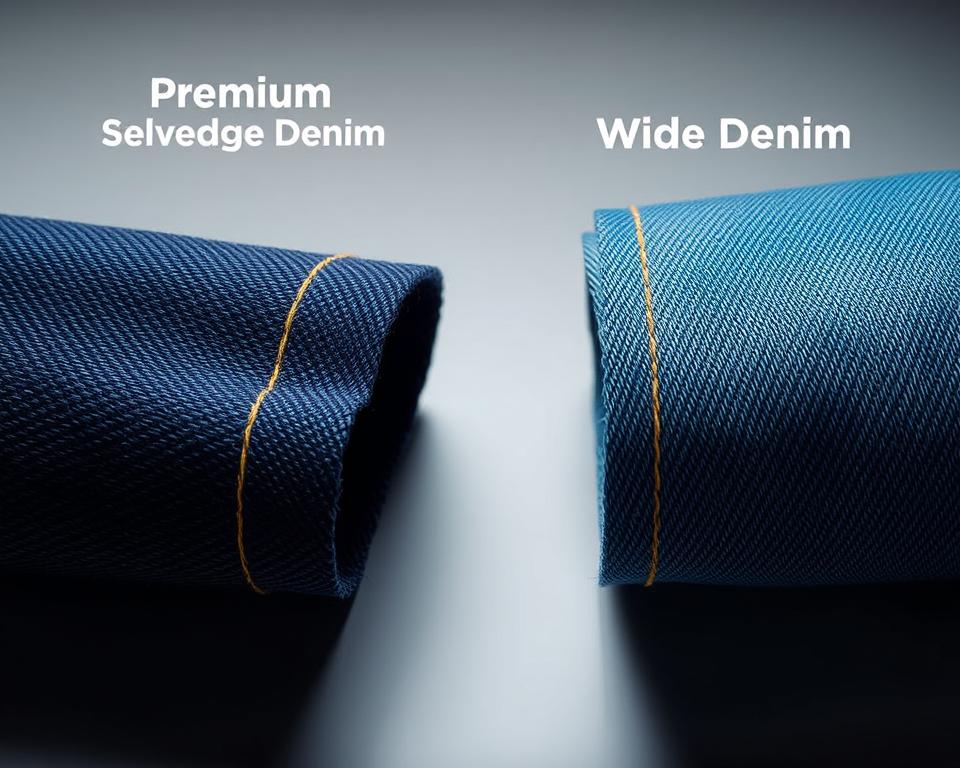

Selvedge Denim vs. Wide Denim

For making long-lasting and trendy pieces, the selection of fabric plays a crucial role. Among the prevalent selections are selvedge and wide denim, each with unique characteristics. Understanding their differences can help you choose the ideal material for your project.

Key Differences in Weaving Techniques

Selvedge denim is woven on classic shuttle looms, yielding limited spans of 30-35 inches. This striped selvedge denim fabric method forms secure finishes, often accented with a distinctive red line. Conversely, wide denim employs advanced projectile looms, yielding widths of 60 inches or more.

Traditional shuttle looms operate at approximately 3 meters per minute, while projectile looms can produce up to 30 meters per minute. Such speed differences influence both the cost and the texture of the final product.

Benefits and Drawbacks

Selvedge denim is known for its premium quality and durability. Its limited breadth renders it perfect for applications where visible hems or patches are desired. However, it can be pricier, averaging $23 per meter.

Wide denim is more cost-effective, ranging at $8 per half-meter. Its broader span reduces waste, ideal for big-scale works like interior décor projects. However, it does not feature the signature finished border of selvedge.

| Attribute | Selvedge Denim | Wide Denim |

|---|---|---|

| Span | 30-35 inches | 60+ inches |

| Technique | Traditional Shuttle | Projectile Loom |

| Output | 3 meters per minute | 30 meters per minute |

| Price | $23 per meter | $8 per half-meter |

For defined borders as seen in Grainline Thayer jackets, selvedge is favored. For larger projects, wide denim offers better value and efficiency. Weigh your requirements carefully to decide.

Working with Selvedge Denim

Working with premium materials can elevate your sewing projects to the next level. Whether you are creating jeans, outerwear, or skirts, grasping fabric quantities, proper sewing methods, and maintenance guarantees a polished result. Let’s delve into how to make the most of this everlasting textile.

Fabric Quantities for Your Projects

When planning your project, calculating the right amount of material is crucial. For men’s jeans, you’ll need about 3-3.3 yards, accounting for potential defects and shrinkage. For trucker jackets, expect to use around 3.3 yards, while skirts can be made with just 2 yards.

Creative pattern placement can help manage imperfections in the material. Instead of cutting around defects, consider integrating them into your design for a unique look.

| Item | Yardage Needed |

|---|---|

| Jeans for Men | 3 to 3.3 yards |

| Trucker-Style Jacket | 3.3 yards |

| Dress | 2 yards |

Advice for Sewing and Longevity

Employing proper equipment and methods leads to an impeccable finish. Opt for #70–110 pins and machine attachments suitable for thick fabrics. Gütermann rPET thread works well for contrasting stitches.

Consider these extra tips:

- Employ a tailor’s clapper to achieve crisp creases without gloss.

- Core Fabrics’ denim kits include topstitch thread, rivets, and 9mm jeans buttons for a professional finish.

- For structured edges, like those in jackets, selvedge is the preferred choice.

Correct care ensures your garments last longer. Use minimal washing and opt for air drying to preserve fabric quality. Following these guidelines guarantees enduring results.

The Final Word

Working with high-end textiles is not solely about longevity; it’s about infusing character. Selvedge denim exemplifies this ideology, merging artisanal charm with enduring excellence. Whether you’re sewing jeans or a structured jacket, this material tells a story with every stitch.

At Core Fabrics, we make it easy to explore your creativity. Experience our swatch service to gauge texture and weight prior to purchase. Additionally, benefit from complimentary shipping on orders exceeding $150 USD throughout North America.

Looking ahead, eco-friendly blends and vintage washes are shaping the future of cotton textiles. These trends offer new ways to add sustainability and style to your wardrobe.

Ready to dive into the world of premium materials? Begin your journey now and appreciate the merit of intentional crafting. Your subsequent creation may well become an enduring classic.